Product Description

Automatic Self Cleaning Filters

We offer worldwide real-time self-cleaning filters: clean themselves automatically when head-loss across the screen reaches a preset value.

Wide range of filtration degrees: from 3500 to 3 micron

Applications of Automatic Self Cleaning Filters

INDUSTRIES

We provide water filtration products and systems as integrated components or as completefiltration solutions For intake, cooling, process, service water and wastewater.

Our filters are built to meet the strict requirements of the industrial sector.

Flexible configuration makes Our filters suitable For installation anywhere along the water system line. In addition to the standard families of filters, We also customizes its products and systems to meet the special requirements of the customer.

IRRIGATION

We are global leader in supplying high-quality filtration and fertigation equipment for: agriculture, turf, landscape, golf and green houses.

Providing protection to all irrigation emitters - from sprinklers to drippers and foggers.

Filtering process of Automatic Self Cleaning Filter:

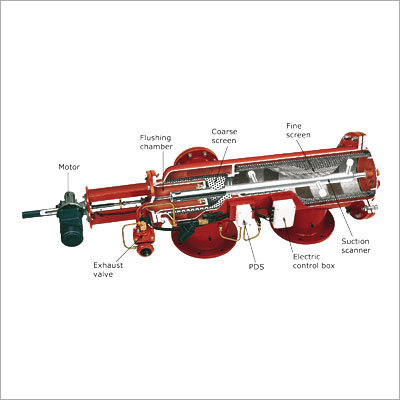

The water enters through the inlet pipe into the coarse screen from outside in, and through the fine screen from inside out. The "filtration cake" accumulates on the fine screen surface and causes head loss To develop. The coarse screen is designed to protect the cleaning mechanism from large dirt particles. It should not accumulate large quantities of suspended solids and is not cleaned automatically.

Automatic Self-cleaning process:

• The automatic self cleaning filter will start the self-cleaning process when the pressure differential across the screen reaches a pre-set value or a predetermined lapse of time.

• Cleaning of the filter element is carried out by the suction scanner, which rotates in a spiral movement while removing the filtration cake from the screen, and expels it out through the exhaust valve. The rotation of the scanner is operated by a 2-way (fwd/rev) drive unit that is attached to the scanner by a threaded shaft, providing the linear movement.

• The exhaust valve is activated For the duration of the cleaning cycle by a 3-way solenoid. During the self-cleaning process, which takes approximately 35 seconds, filtered water continues To flow downstream.

| Comparison between Automatic Self Cleaning & Pressure Sand Filter |

| | |

| Points Of Comparison | Automatic Self-cleaning | Pressure Sand Filter |

| Type Of Cleaning Operation | On line : Automatic Self-cleaning | Off line : Manual |

| Filtration During Backwash | Continuous Filtration : Filters during Backwash | Filtration Stops : Filtration stops during Backwash. |

| Back Wash Cycle Time | Very Short : 1.0 - 1.2 Min. | Very Long : 10 - 15 Min. |

| Waste Water Per Day | Minimum : 1.5 % of the rated flow per day | Very High : 20 - 30 % of the rated flow per day |

| Filtration Quality | Consistent : Consistent quality between two Backwash cycle | Inconsistent : Quality disproves over period of time |

| Foot Print | Very Small : 1.0 X 5.0 X 1.0= 5.0 m2 | Very Large : 2.0 X 10.0 X 3.0=20.0 m2 |

| Maintenance | Low & Short Time : Screen can be easily removed & cleaned physically, with negligible shut down time | High & Long Time : Man power required & Very long shut down time. |

| Operating Cost | Very Low : As no man power required & very lo back wash water | Very High : Manpower required for operation & high quantity of water required for backwash |

| Pay Back Time | < 4 Years | |

high or low volume irrigation, using fresh, brackish or recycled water.

MUNICIPAL

We are committed to successfully developing, manufacturing and distributing water treatment and filtration solutions For Potable Water and Wastewater, in applications such as pre-filtration For MF,UF, NF and RO membranes, UV and tertiary treatment, and polishing.

Our products and systems enable our clients to achieve their full potential For supplying clean water systems.

Automatic Self-Cleaning Water Filters

ü Real-time self-cleaning filters: clean themselves automatically when head-loss across the screen reaches a preset value.

ü Uninterrupted water supply: the filter cleans itself in just seconds without interrupting downstream flow.

ü Modular structure: different diameters, suitable For use singly or in manifold configuration providing optimal solutions To meet specific customer requirements.

ü Flexibility of control options: Hydraulically or electronically controlled units. Electric control boards To suit specific needs.

ü Flushing according To pressure differential and/or according To time. Continuous flushing, alarm signals, flushing counter

and more.

ü Wide range of filtration degrees: from 3500 To 3 micron